What do we do when we have ideas in our minds? We give them shapes using pen and paper. The invention of computers and internet technology made it easy to share and visualize our thoughts. Furthermore, with the advent of printing technologies, we can now send the virtual document for printing with just a click. All this helps us bring our ideas to life on a piece of paper in 2D.

Now, what if we tried to replicate our imaginations and create anything that we could think of in 3D? Yes, that sounds exciting. In a world where imagination knows no bounds, 3D printing is a fascinating gateway for turning imagination into reality.

A cubic structure printed by a 3D printer

Imagine a magical machine that can bring objects to life layer by layer, like a wizard conjuring wonders from thin air. 3D printing, also known as additive manufacturing, achieves just that!

3D printing harnesses the power of technology to build intricate, three-dimensional structures. Its applications range from tiny trinkets to awe-inspiring architectural wonders to even living tissues: eyewear, footwear, furniture, dental products, prosthetics, and fossil reconstruction. However, regenerative health care is one prominent area of 3D printing’s applications.

Printing tissues by 3D Bioprinting

A 3D-printed heart in front of a 3D printer

The magical tool of 3D printing technology can fabricate live tissues in a method known as 3D bioprinting or biofabrication. Any desired biological structure, ranging from tissues to organs, can be created with the 3D bioprinter.

At first, a digital blueprint of the structure is built using specialized software. Then, the bioprinter crafts the design in 3D using a distinctive ink made of viable cells. Following the digital blueprint, the cells are deposited gradually in layers, and finally, your coveted structure is brought to life in 3D. The process is much like making your favorite toy come alive with the help of a printer.

3D bioprinting is finding great value in the health sector. This new technology is creating opportunities that can bring about a radical change in the field of medical research. The major advantages are-

- The technology can potentially reduce organ transplant rejection by employing the patient’s own cells for printing, thus lowering the danger of immune system reactions.

- It has the potential to replace animal testing in laboratories, saving millions of animals from pain and death.

L’Oreal’s use of bio printed tissue for cosmetics research is a significant achievement in this regard, providing cruelty-free alternatives and supporting ethical practices.

- Bioprinting has the potential to revolutionize drug testing by replacing human volunteers with bioprinted tissue. This method could improve the safety and efficiency of assessing new pharmaceuticals before they are approved for human use.

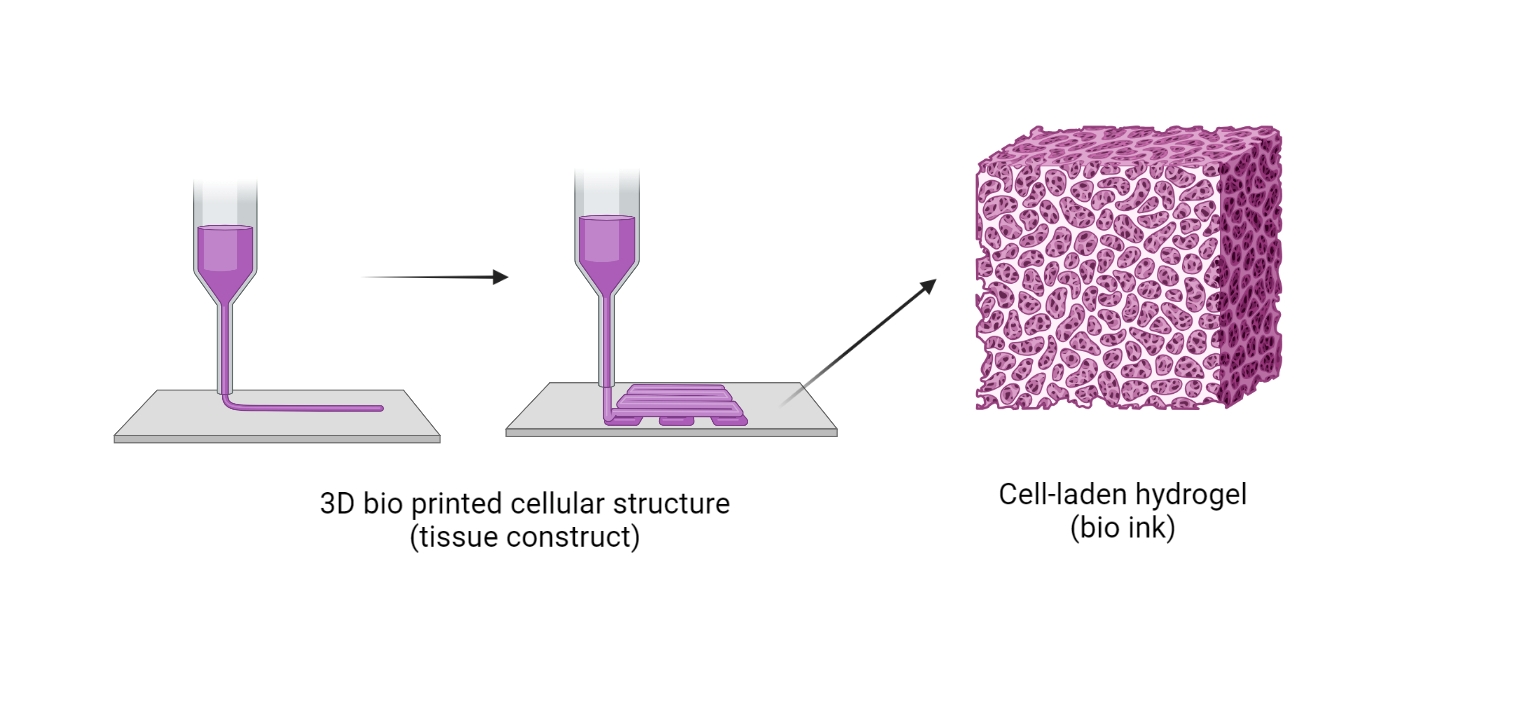

However, creating live human tissues is difficult because of their natural complexity and intricate vasculature. Therefore, unique materials called “bio-inks” have been developed that act like glue to hold living cells together in a hydrogel during and after printing.

The ‘magical’ bio-inks

Bio-inks are not regular inks; they are bioprinting wizards. They organize the assembly of live cells into complex structures, like a conductor leading an orchestra. Besides, they nurture cells, keeping them alive and healthy as they join together to form 3D structures.

Bio-inks can be either natural or synthetic in nature. Currently, the natural bio-inks that are in use are non-human in origin. They usually come from animal sources, like collagen and gelatin. On the other hand, synthetic bio-inks like polyethylene glycol (PEG) and polyvinylpyrrolidone (PVP), are engineered using chemicals and polymers to mimic the properties of natural tissues.

A schematic diagram of cell structure printing

Challenges to 3D bioprinting

Despite potential revolutionary applications, 3D bioprinting technologies also face some challenges that are yet to be conquered. Developing an appropriate bio-ink that is compatible with the 3D printing technology determines the successful outcome of the process. The major requirements for a suitable bio-ink are-

- Bioprinting inks have to be structurally stable with proper biochemical properties to avoid collapsing under their own weight after printing is done.

- The live tissues of natural bio-inks should remain viable both during and after the printing process.

This demands that the formulation withstand the high temperature and pressure conditions that prevail during the printing process. This constraint limits the options for components to be used as bio-inks and thus affects the printing performance.

- 3D bioprinters are highly specialized machines that are designed to handle biological materials. These machines can be quite costly to purchase and maintain. Moreover, creating appropriate bio-inks and optimizing printing techniques necessitate substantial research and development efforts, which can add to the cost.

- Additionally, the sources of natural bio-inks are totally animal-dependent, and there is a huge need for animal-free alternatives in laboratories. Although synthetic bio-inks can work as a good animal-free alternative, the use of synthetic polymers in 3D biofabrication oversimplifies the complex natural processes that exist in the human body.

In his briefing, Dr. Markus Lunzer, Materials Specialist at UpNano, says, “The technology has made some tremendous advances in performance but is now mainly limited by the absence of high-performing biological materials”.

Human ‘3D’ inks: The silver lining

The Human BioInks for 3D Printing (HU3DINKS) project was launched and integrated into the framework of International Research Activities by Small and Medium-sized Enterprises (IraSME). IraSME is a coalition of government organizations and funding agencies which oversees national and regional funding initiatives for cooperative research projects involving small to medium-sized enterprises (SMEs). These projects also involve the active participation of research and technology organizations (RTOs). The HU3DINKS project addresses the challenges of 3D bioprinting technology and aims to foster cross-border collaborations between member countries.

“The HU3DINKS project can induce a paradigm shift in the field by truly mimicking the human cellular environment both in terms of architecture and composition,” says Dr. Markus Lunzer, Materials Specialist at UpNano.

HU3DINKS aims at developing a new form of natural bio-ink that is fully human tissue-based and has high performance. It is also expected to be compatible with all the current 3D bioprinting technologies, including extrusion printing and high-resolution laser-based printing.

There are some commercial human tissue-derived materials available on the market as bio-inks, like platelet-rich plasma (PRP), demineralized bone matrix (DBM), extracellular matrix (ECM) derived components, and various stem cell types. However, these biomaterials have poor bioactivity and printing performance in the 3D bioprinter. The HU3DINKS project plans to enhance the performance ability of all these commercially available human tissue-derived materials into potent bio-inks that can be printed directly.

3D Bioprinting at subcellular resolution

One of the major purposes of using animals for drug testing is to get more accurate results of the drug’s effect on a living body. To replace animal models with human 3D-printed tissues, the complexity of natural tissues should be precisely replicated.

Mimicking the complicated framework of cellular structures at subcellular resolution can now be achieved with the new high-resolution bioprinting technology. It is based on the 2-photon polymerization (2PP) principle.

2PP is a direct laser-writing technique allowing the fabrication of 3D structures at a subcellular resolution where two photons are absorbed simultaneously from high-intensity laser beams. It is the only technology available now that allows the printing of complex microcellular structures. It also helps with quick drug screening through direct printing on microfluidic chips.

A 3D printer printing DNA

The Future of 3D Bioprinting

The latest 3D bioprinting technology is predicted to have significant applications. If successful, the technology can be effective in accurate tissue regeneration and organ printing, which will have a huge impact on many human lives. In this regard, Dr. Jasper Van Hoorick, the CEO of BIO INX, commented that while many obstacles still remain to be overcome before making it a clinical reality, bioprinting technology has been successful in providing animal-free testing in laboratories.

Drugs or cosmetics can now be tested on human 3D tissues instead of conventional 2D cell culture techniques. The printed human 3D tissues form better representations of the natural tissues present in the human body. This outlook follows the 3R principle of reducing, replacing, and refining animals in laboratories that are sacrificed for scientific purposes.

If you enjoyed reading this post, please subscribe to our newsletter or Visit our Shop to buy some geeky science merchandise.

1 comment

[…] a pioneering field in biomedical research, leverages electrical stimulation to activate specific genes within living organisms. This […]