655

|

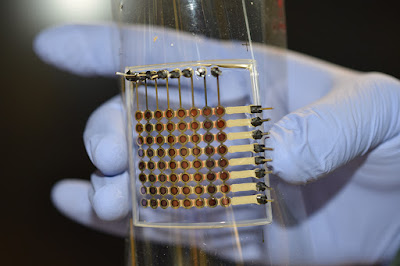

| Image credit: University of Minnesota |

The researchers at the University of Minnesota Twins Cities have developed a fully 3D-printed, flexible OLED display using a customised printer that can print objects for you. This finding can help to produce low-cost OLED displays in the coming years, instead of technicians using costly microfabrication facilities to construct small-scale structures such as computer chips, smartphone displays, etc. The detailed study is published in Science Advances.

OLED Technology- Overview

OLED stands for Organic Light-Emitting Diode- a technology that uses LEDs to produce light by organic molecules. This technology helps to create the world’s best display panels.

Organic displays are prepared by placing thin films of organic semiconductors such as silicon or gallium arsenide between two conductors. These films emit a bright light when an electric current is applied. Each pixel emits its own light and is controlled individually, unlike LCDs in which light is produced by a backlighting unit (illumination unit that does not produce its own light).

OLEDs can be flexible and are used in large electric devices like monitors and televisions, as well as in micro devices such as smartphones and tablets. This display technology has numerous advantages over other technologies concerning device weight, power efficiency, flexibility, high contrast ratio and wide viewing angle.

“OLED displays are usually produced in big, expensive and ultra-clean fabrication facilities,” said Michael McAlpine, the senior author of the study. “We wanted to see if we could basically condense all of that down and print an OLED 3D display on our tabletop 3D printer, which was custom built and costs about the same as a Tesla Model S.”

The Making of The OLED Display

Previously, researchers tried to print 3D OLED displays, but they faced challenges in obtaining uniformity of the light-emitting layers on the entire screen. Other teams partially printed displays but depended on spin coating or thermal evaporation to form functional devices. Spin coating refers to the process of depositing uniform thin films on flat substrates or image bases whereas, thermal evaporation is the process of applying coatings of pure metals on objects.

The new OLED display study uses a combination of two different printing modes to print the six layers required for a functional display. The researchers used extrusion printing where materials are dispensed through a nozzle to manufacture circuit connectors, electrodes, insulation and encapsulation, while the spray printing technology was used to deposit the active layers by a 3D printer at room temperature. Spray printing leads to improving the uniformity of light-emitting layers. The prototype had 64 pixels and was 1.5 inches wide. Every pixel worked and emitted light.

“I thought I would get something, but maybe not a fully working display, ”- said Ruitao Su, the first author of the study. “But then it turns out all pixels were working, and I can display the text I designed. My first reaction was ‘It is real!’ I was not able to sleep the whole night.”

“The display was also flexible and could be packed in a microcapsule or encapsulating material which could make it useful for future applications, ”- she added.

The researchers are aiming to build a 3D OLED display that has a higher resolution with improved brightness.

“The nice part about our research is that the manufacturing is all built-in, so we’re not talking 20 years out with some ‘pie in the sky vision, ”- said McAlpine. “This is something that we actually manufactured in the lab, and it is not hard to imagine that you translate this to printing all kinds of displays ourselves at home or on the go within just a few years, on a small portable printer.”